Aftermarket modifications are a popular way to personalise your vehicle and improve its performance, but many car owners don’t realise the impact these changes can have on their car’s electrical system. From upgraded sound systems to custom lighting, each modification places additional demands on your vehicle’s electrics. Understanding how these changes affect your car can help you avoid costly repairs and keep your vehicle running safely on Auckland’s roads.

Common Aftermarket Modifications That Impact Your Electrical System

Audio and Entertainment Upgrades

One of the most popular aftermarket modifications is upgrading your car’s audio system. While a new head unit or set of speakers might seem straightforward, high-powered amplifiers and subwoofers draw significantly more current than factory systems. Your car’s alternator and battery were designed to handle the original equipment, so adding power-hungry audio components can strain these parts. In many cases, car owners find their battery draining faster or their headlights dimming when the bass hits, both signs that the electrical system is struggling to keep up.

Installing a quality audio system requires more than just connecting wires. Proper grounding, appropriately sized cabling, and sometimes a secondary battery or upgraded alternator are necessary to prevent electrical issues. Without these considerations, you risk damaging sensitive electronic components throughout your vehicle. A professional auto electrician can assess your current system’s capacity and recommend the right upgrades to support your new audio equipment.

Aftermarket Lighting

Custom lighting modifications, such as LED light bars, underbody lights, or upgraded headlights, are another common change that affects your car’s electrics. While LED lights are generally more energy-efficient than traditional bulbs, many aftermarket lighting setups still increase the overall electrical load on your vehicle. Light bars used for off-road driving in areas around Auckland can draw substantial current, especially when multiple units are installed.

The way aftermarket lights are wired is just as important as the lights themselves. Poor wiring practices can lead to shorts, blown fuses, or even electrical fires. Some aftermarket HID or LED headlight conversions can also interfere with your car’s onboard computer systems, triggering warning lights or causing flickering. Using relays, proper fusing, and quality wiring harnesses ensures that your lighting modifications work safely without overloading your vehicle’s electrical system.

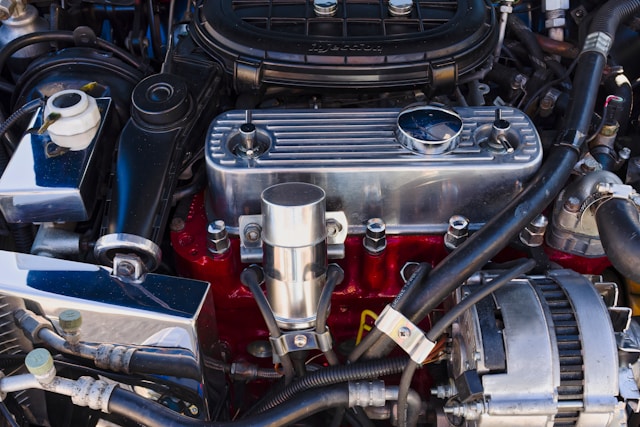

Performance Chips and Engine Tuning

Performance chips and ECU (Engine Control Unit) tuning are modifications designed to increase your car’s power output and improve fuel efficiency. These devices alter the way your engine’s computer manages fuel injection, ignition timing, and other parameters. While the performance gains can be appealing, these modifications directly interact with your vehicle’s most critical electronic systems.

Installing a performance chip incorrectly or using a low-quality product can cause communication errors between your ECU and other vehicle systems. This can result in check engine lights, poor running conditions, or even damage to your engine and transmission. Some chips also increase the electrical demands on your ignition system, which may require upgraded coils or spark plugs to handle the additional load. Working with an experienced auto electrician ensures that any performance modifications are compatible with your vehicle and properly integrated.

Security Systems and Remote Starters

Aftermarket alarm systems and remote starters provide convenience and peace of mind, but they also add complexity to your car’s wiring. These systems tap into multiple circuits, including the ignition, door locks, and starter motor. When installed incorrectly, they can cause intermittent starting issues, drain your battery, or interfere with factory security features.

Modern vehicles have sophisticated immobiliser systems that communicate with the key fob to allow the engine to start. Aftermarket remote starters need to bypass or integrate with these systems, which requires precise knowledge of your specific vehicle’s wiring. A poorly installed system might work initially but develop problems over time as connections loosen or corrode. Professional installation ensures that all connections are secure and that the system operates without affecting other electrical components.

How Modifications Affect Your Alternator and Battery

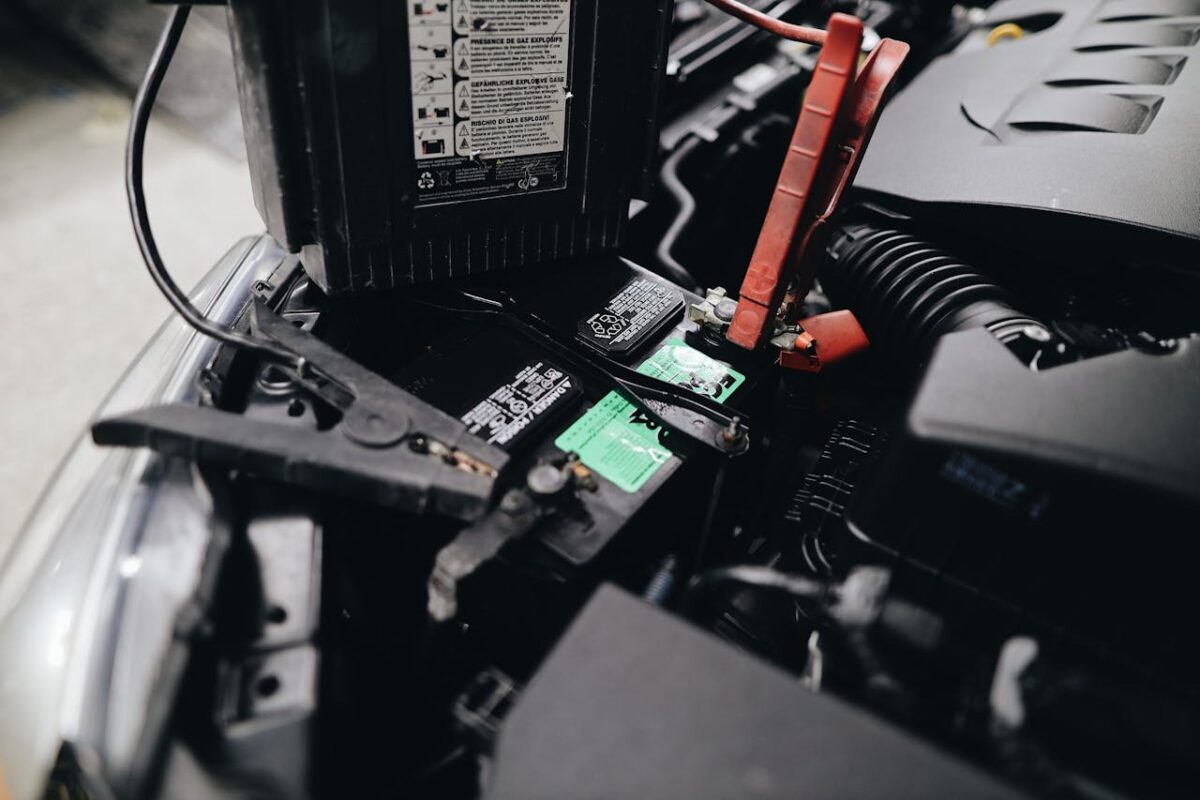

Increased Electrical Load

Every electrical component in your vehicle draws power from the battery, which is recharged by the alternator while the engine runs. Your car’s electrical system was designed with a specific capacity to handle the factory-installed components. When you add aftermarket accessories, you increase the total electrical load, which can exceed what your alternator can supply. This imbalance leads to the battery being drained faster than it can be recharged, resulting in starting problems and reduced battery life.

Signs that your electrical system is overloaded include dimming lights when accessories are in use, slow engine cranking, and a battery that frequently goes flat. If you’ve noticed any of these symptoms after installing modifications, it’s worth having your charging system tested. An auto electrician can measure the output of your alternator and compare it to the total draw of your accessories to determine if an upgrade is needed.

Upgrading Your Charging System

For vehicles with significant aftermarket modifications, upgrading the alternator or adding a secondary battery may be necessary. High-output alternators can provide the additional current needed to keep up with power-hungry accessories while still maintaining the battery’s charge. A secondary battery, often installed in the boot or under a seat, can power accessories independently from the main starting battery, ensuring you can always start your car.

Choosing the right upgrades depends on the specific modifications you’ve made and how you use your vehicle. An auto electrician can calculate your total electrical load and recommend an alternator with sufficient output. They can also advise on battery types and configurations, such as deep-cycle batteries for audio systems or AGM batteries for better performance and durability.

Wiring and Installation Quality

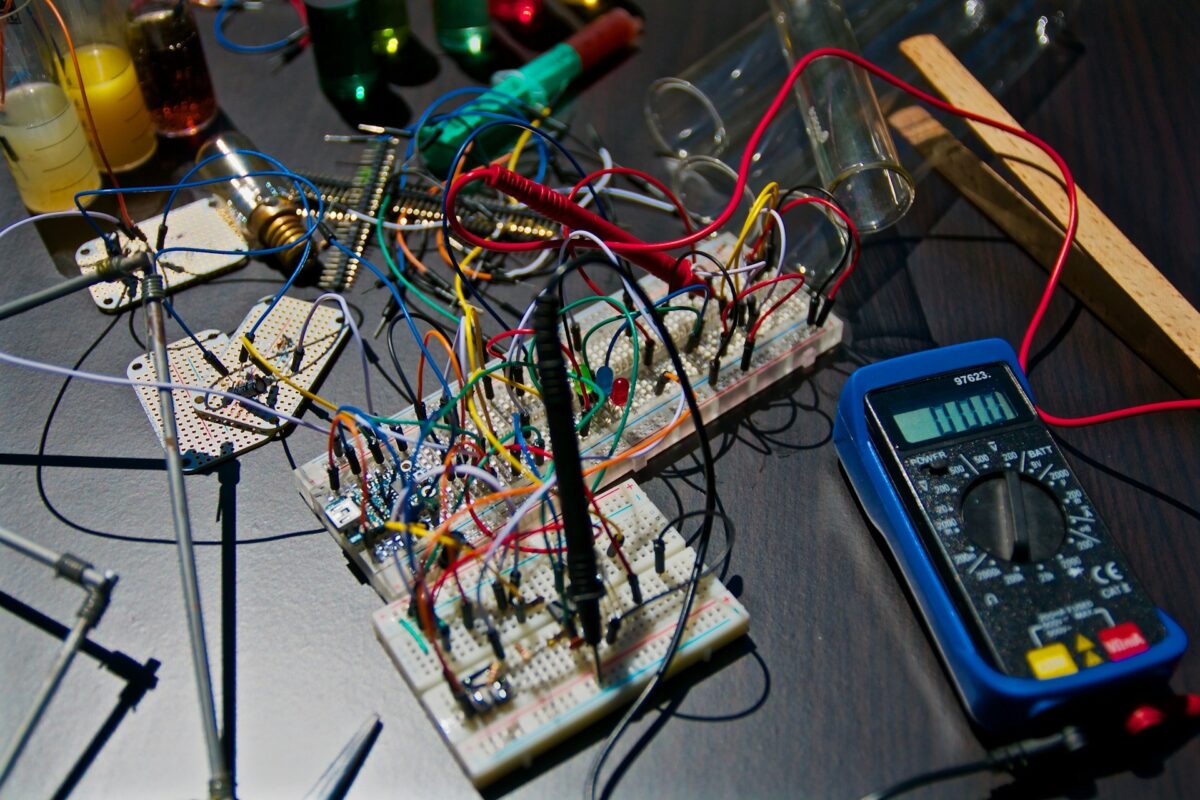

The Importance of Proper Wiring

The quality of wiring and installation is one of the most critical factors in how aftermarket modifications affect your car’s electrics. Using undersized wires for high-current accessories can cause the wires to overheat, potentially melting insulation and causing shorts or fires. Poor connections that aren’t properly crimped or soldered can develop resistance over time, leading to voltage drops, intermittent operation, and further heating.

Factory wiring is designed to handle specific loads with appropriate fuse protection. Aftermarket installations should follow the same principles, using wire gauges rated for the current draw of each accessory and fuses or circuit breakers to protect against overloads. Routing wires away from heat sources and moving parts also prevents damage and ensures long-term reliability. Taking shortcuts during installation might save time initially, but it often leads to problems that are more expensive to fix later.

Grounding Issues

Proper grounding is essential for any electrical installation, yet it’s one of the most commonly overlooked aspects of aftermarket modifications. A poor ground connection increases resistance in the circuit, causing accessories to operate poorly or not at all. Symptoms of grounding issues include flickering lights, erratic gauge readings, and interference in audio systems such as whining or buzzing noises.

Each aftermarket accessory should have a solid ground connection to the vehicle’s chassis or a dedicated grounding point. Using star washers or scraping away paint ensures metal-to-metal contact for the best conductivity. For vehicles with multiple modifications, a grounding distribution block can provide organised and reliable connections for all accessories. An auto electrician can inspect your current grounding setup and identify any issues that might be causing electrical problems.

Interference with Vehicle Computer Systems

CAN Bus and Communication Protocols

Modern vehicles use a Controller Area Network (CAN bus) that allows various electronic modules to communicate with each other. This network controls everything from engine management to airbag deployment and power windows. Aftermarket modifications that tap into the CAN bus or interfere with its signals can cause unpredictable behaviour throughout the vehicle. Warning lights might illuminate without cause, features might stop working, or the vehicle might enter a limp mode that restricts performance.

Some aftermarket accessories are designed to integrate with the CAN bus to provide features like automatic light control or gauge displays. However, using incompatible devices or incorrect installation can introduce electrical noise or false signals into the network. Diagnosing CAN bus issues requires specialised equipment and knowledge, making it important to work with professionals who understand these systems.

Diagnostic Trouble Codes

When modifications interfere with your vehicle’s systems, the onboard computer often logs diagnostic trouble codes (DTCs) and illuminates warning lights on the dashboard. These codes indicate which system has detected a fault, but the root cause might not be immediately obvious when aftermarket components are involved. For example, an aftermarket exhaust modification might trigger an oxygen sensor code, even though the sensor itself is functioning correctly.

Clearing codes without addressing the underlying issue only provides a temporary solution, as the codes will return once the computer detects the problem again. An auto electrician with experience in modified vehicles can interpret these codes in context and trace the issue to its source. They can also advise on whether certain codes can be safely ignored or if modifications need to be adjusted to prevent ongoing problems.

Protecting Your Vehicle and Your Investment

Choosing Quality Components

The quality of aftermarket components you choose directly affects how well they integrate with your car’s electrical system. Cheap components often use inferior materials and manufacturing processes, leading to early failure or compatibility issues. Investing in reputable brands with good reviews and proper certifications reduces the risk of problems and often provides better long-term value.

Quality components also tend to come with better documentation and support, making installation easier and more reliable. Some manufacturers provide vehicle-specific wiring harnesses and mounting kits that simplify the process and reduce the risk of installation errors. While the upfront cost might be higher, the reduced risk of damage to your vehicle and the longer lifespan of the components make it worthwhile.

Professional Installation

While some modifications can be completed by confident DIY enthusiasts, professional installation offers several advantages that protect both your vehicle and your investment. Auto electricians have the training and experience to understand how modifications will interact with your specific vehicle’s systems. They use proper techniques and tools to ensure connections are secure and components are protected.

Professional installation also provides accountability if something goes wrong. A reputable auto electrician will stand behind their work and address any issues that arise. This peace of mind is particularly valuable for complex installations or when modifying newer vehicles with sophisticated electronic systems. The cost of professional installation is often far less than the cost of repairing damage caused by improper DIY work.

Regular Inspections and Maintenance

Aftermarket modifications require ongoing attention to ensure they continue to function properly without causing issues. Connections can loosen over time due to vibration, and wiring can become damaged from heat or abrasion. Regularly inspecting your modifications and having them checked during routine services helps catch problems before they become serious.

If you notice any changes in how your modifications perform, such as reduced output from your audio system or dimmer lights, it’s worth having the installation inspected. Early detection of issues like corroded connections or failing components prevents more extensive damage and keeps your car running reliably.

Need Help With Your Car’s Electrical Modifications?

Aftermarket modifications can transform your vehicle, but they need to be installed correctly to avoid damaging your car’s electrical system. From audio upgrades to performance tuning, each modification requires careful planning and professional installation to work safely and reliably.

As Auckland’s trusted auto electricians, Eurosparx can help you with all aspects of aftermarket electrical modifications. Whether you need advice on upgrading your charging system, professional installation of new accessories, or diagnosis of electrical issues in a modified vehicle, our experienced team is here to help. Contact us today by calling 09 218 7789 to discuss your requirements.